In Brief

In some states, mandates have been put in place requiring that public education leaders show successful implementation of Continuous Improvement programs and initiatives. Even in states where it isn’t mandatory, organization who implement Continuous Improvement methods at a system level are better poised to navigate rapid change and maintain healthy enrollment in the competitive environment brought on by school choice.

Summary

- Using Continuous Improvement methods, K-12 organizations can prepare for the shifting needs of students and approach improvement proactively using data.

- Most improvement initiatives fail because they are reactionary and isolated.

- Continuous Improvement is focused on intentional cycles of improvement where improvement efforts are consistently assessed and adjusted.

Why Do Improvement Initiatives Fail?

Organizations often take a reactive approach to the need for improvement. Improvement programs are implemented because of a specific problem or external factor that has already occurred. Since the organizations is participating in improvement programs, leaders might confuse these initiatives for organization-wide Continuous Improvement. But many of these approaches don’t take into consideration the entire organization, or the full context of the implementation. Programs that are reactive to changes only seek to course correct, not create sustained organization-wide improvement.

A variety of improvement initiatives in targeted areas doesn’t equal Continuous Improvement. It’s too common for new initiatives to fizzle out or be replaced by newer initiatives. Employees keep hearing about the next approach to improvement that the organization will adopt. This can cause initiative fatigue, as employees grow tired of implementing the next improvement tactic only to see it fade away, unsuccessfully. In this model, the concept of Continuous Improvement loses its meaning and becomes a buzz word that gets thrown around every time a new initiative is introduced.

What Makes Continuous Improvement Different?

Continuous Improvement is a proactive, systematic analysis of data that informs improvement efforts and always includes development of leadership skills. Unlike a reactive approach, Continuous Improvement considers the impact of action on the entire system.

When practicing Continuous Improvement, decisions are based on what is most needed for organization-wide improvement, not based on external trends. Systematic improvement isn’t a rapid initiative that can be applied overnight. It is a long-term improvement process that continuously evolves with the needs of the organization.

Using Continuous Improvement, education organizations can prepare for change and approach it proactively using data rather than reactively once an external force demands the improvement.

Commit to a Continuous Improvement Mindset

Leaders who adopt a cycle of planning, review progress, adjust and practice reflection can more accurately predict and control the organization’s success. Establishing a Continuous Improvement mindset is key to sustaining and increasing results year after year.

Leading With Continuous Improvement

Break Down Goals to Determine Focus – A strategic vision and goals for the next several years are important for organizations to know. Teams perform better when those goals are further broken down to show individuals how their responsibilities lead to the achievement of the organization’s priorities. Define quarterly outcomes for each annual goal.

Use Progress to Plan – Using timely data aligned to the goals, individuals and leaders can make educated judgments about the probability of hitting goals or make necessary adjustments. It’s best to review progress and reflect in 45-, 60-, or 90-day cycles.

Own the Goal – Most education organizations have multiple annual goals for focus and alignment. To ensure achievement of goals, assign an executive leader to each annual goal. The owner of the goal is responsible for maintaining focus on the goal, monitoring progress and communicating information about the goal to the team and the executive leader.

Focus on What’s Important – Achieving the goals set each year and sustaining success demands a narrow focus on the strategic actions that matter. Distraction from new ideas and initiatives throughout the year can get in the way of progress on results. Success depends on aligning the team’s focus to specific priorities. Less is more.

Analyze Processes – Success often depends on better execution. If there are barriers in processes, they can slow down productivity and cause good employees to experience frustration and disengagement. Create alignment between goals, actions and processes by documenting processes and identifying areas for improvement.

Make Reflection a Priority – To improve as a team or an individual, it is critical to pause and examine what is getting positive results, what’s not working and what actions and adjustments will achieve the intended outcome. It’s not enough to just reflect. Communicate the results of reflection to keep teams aligned and committed to the goals.

Celebrate Progress – As incremental progress is made, it’s important to recognize how far the team has come and to celebrate those wins. Progress is the fuel to motivation. Prevent burnout by identifying and acknowledging milestones and contributors along the way. Meaningful progress builds momentum and connects team members to the purpose of the work.

What Does Continuous Improvement in K-12 Education Look Like?

Rather than implementing one failed management fad after another, when organizations commit to Continuous Improvement, data is used to plan, experiment, analyze and implement the most productive improvements across the system. There are several tools used by exemplary districts to implement Continuous Improvement practices to maximize improvement for school systems.

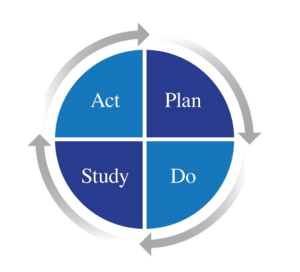

The PDSA Model

The “Plan. Do. Study. Act.” Model (PDSA) is designed to run in cycles, which compliments the pressure for continuous change the faces education. As results are studied in each PDSA cycle, plans are made for the next round of action. PDSA allows leaders to test if ideas for improvement work, before implementing them throughout the organization. Rapid cycles of PDSA can lead to faster, successful system changes.

If there are additional changes in the external environment, PDSA cycles allow space to gather results related to those changes. This gives organizations more accurate information for decision making. Based on the data received, make modifications to the plan and repeat the PDSA cycle. You may even find that completely abandoning the first approach and repeating the cycle is necessary.

PDSA is one of the most frequently used Continuous Improvement methods in and out of education. Dating back to the 1930s, these cycles were introduced to offer an ongoing approach to reducing variance in business and manufacturing. PDSA is now applied in Carnegie-recognized systems like the School District of Menomonee Falls to make improvement a constant practice in the organization.

These four steps can be repeated as part of an ongoing process of Continuous Improvement. Other process improvement frameworks include DMAIC (Define, Measure, Analyze, Improve, Control) and Carnegie Foundation’s Six Core Principles for Improvement.

Plus/Delta

Plus/Delta is a simple Continuous Improvement tool that incorporates team member feedback to inform improvement actions. It is a group exercise that allows the team to intentionally reflect on outcomes and adjustments.

Conducting a Plus/Delta session:

- Draw a two-sided chart on a piece of paper, flipboard, white board, etc.

- Write “plus” or “+’ on the left side of the chart. Record wins and what went well under this heading.

- Write “delta” or “Δ” on the right side of the chart. Record opportunities for improvement and next action steps under this heading.

The review of processes and practices to determine what works well and what needs to be adjusted encourages a culture of improvement. Use this technique to gather specific feedback about an event, process or situation. While it is important to collect the feedback, it’s the commitment to action that creates trust and improvement. After conducting a Plus/Delta, create a plan to improve the process based on the data from the Delta side of the chart. Then communicate and execute the plan.

Root Cause Analysis

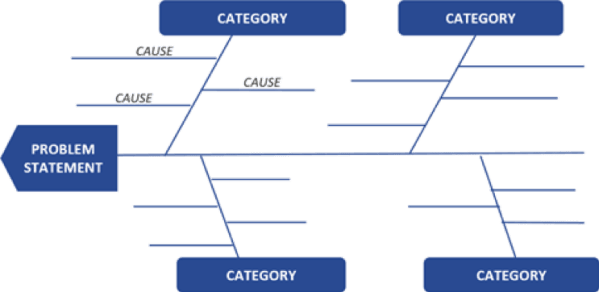

Fishbone Diagram

A Fishbone Diagram is a Continuous Improvement tool that guides teams in getting to the root cause of variance before moving forward with actions to improve. Once the team is clear on the root cause, a best course of action can be determined. Working within a structure can make root cause analysis run much more smoothly. A cause-and-effect diagram, sometimes referred to as Ishikawa Diagram after its creator, Kaoru Ishikawa, is a structured team process that assists in identifying underlying factors or causes of variation within a specific event. Simply, it’s brainstorming in a structured format. As suggested by the word “fishbone”, these diagrams are structured in this manner:

When working on a Fishbone Diagram, you may find that there could be several problems related to your project that need to be addressed. However, do not attempt to answer them all using one diagram. Give each problem its own diagram to reach individual root causes. You may find these five steps for on how to complete your team’s Fishbone Diagram helpful.

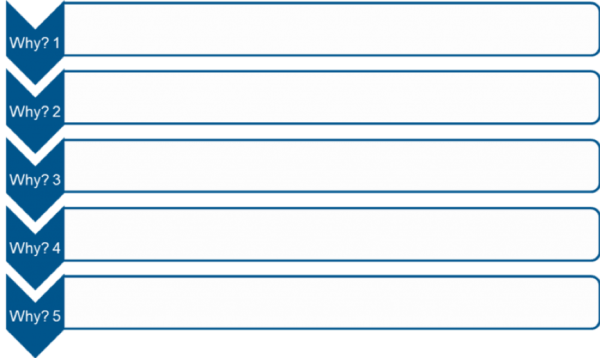

5 Whys

5 Whys is another Continuous Improvement method that prompts teams to focus on the root cause of a needed improvement. The 5 Whys begins by first stating the problem, followed by a sequence of asking “Why” in response to each answer. Each questions probes deeper into root cause, engaging higher order thinking skills to find meaning. This process will often challenge people’s understanding of the problem or situation.

Try it by guiding the team to clearly state a problem or improvement needed. Ask the first “Why,” based on the problem statement. Continue by asking the next “Why,” based on the response to the first question until the team has asked and answered at least 5 Whys. Determine an action step to improve the problem or prevent it from happening in the future.

Action Plan

Most organizations have access to a lot of data. In reviewing this data, decision makers should consider how it can be used for improvement. The first step to improvement is acting on the information. To reach goals, there must be specific actions outlined that achieve success. An action plan is a structured process to move from data to action. The action plan is then used to document the actions, persons responsible and the time frame in which the action will occur. Use the action plan to document progress at least every 30 days.

| Pillar | Annual Goal | Priority | Action Item(s) | Progress Results | Responsible Person |

|---|---|---|---|---|---|

| People | Increase overall score on Employee Engagement | Make efficient use of time in staff meetings. | Send agenda 24 hours in advance of all meetings. | (Yes/No) ballot following team meeting | Unit leaders and team leaders |

| Survey from 3.75 to 3.85. | Start and stop meetings on time. | Pulse Check Survey | Unit leaders and team leaders | ||

| Assign and timekeeper for all meetings. | Stoplight vote (green, yellow, red) | Unit leaders and team leaders |

Successful Continuous Improvement requires understanding the full context of the issue. It also requires using data to develop a plan that is sustainable organization wide.

Learn more about Continuous Improvement success in the School District of Menomonee Falls by visiting this series of articles and webinars providing the top 10 Continuous Improvement strategies for implementing, sustaining, and seeing results from Continuous Improvement efforts in a school district.

KEY TAKEAWAYS

-

Think differently.

Shift from implementing reactionary initiatives that often don’t succeed and begin viewing improvement as a system-wide practice at the foundation of every action taken in the organization. -

Plan differently.

Use data to inform decisions and develop action plans aligned to improvement goals. Break those goals down into quarterly goals. -

Act differently.

Implement a systematic framework for Continuous Improvement in 30-, 45- or 90-day cycles, and use higher-order tools to analyze the root cause of problems.